On 11th February, the first of the HL-series Double Quarter Wave (DQW) cavity was welded, with a frequency close to expectations.

Once the last sheet metal forming and machining steps were performed on the cavity parts with outstanding precision, the subcomponents were welded as from the 4th of February and completed on the 11th with the last weld.

The two final welds are a crucial step in the manufacturing of the crab cavities as they need to be perfect from the first trial. No defect can be accepted, as the possibility of repair is extremely limited. Being an SRF object, the internal surface of the cavity surface must be as smooth as possible which requires a special type of welding parameters and requires a good shape accuracy of the parts and extensive testing beforehand.

Radiofrequency cavities are devices that are used to make electromagnetic fields interact with the beams of charged particles in an accelerator, to different ends like accelerate, or in this case, to rotate or “crab” the packets of particles, called bunches. Like the way a guitar uses pressure waves to produce sounds, cavities sustain electromagnetic waves that resonate at a specific frequency or tone, which is intrinsically related to its shape. Therefore, compact cavities like the DQW, are required to respect very tight shape tolerances to ensure that the fields are in tune with the beam, amongst other things that will affect the performance of the accelerator. To get an idea, at this stage of the manufacturing process, the frequency of this cavity can only deviate by a 0.025% from the given target.

Welding distortion has a significant impact on the cavity frequency, and is now undergoing calibration to compensate for this effect. This step consists of a controlled mechanical deformation of the cavity to bring its poles closer together, thus shifting the frequency downwards towards its target value.

The following steps include, among others:

- Warm RF measurement

- Helium Leak testing

- Metrology

- Bulk BCP

- Cold RF testing

- Helium tank jacketing

- Cold RF testing

The crab cavities are the heart of the deflection system to be installed for the HL-LHC during LS3 in 2026, so their completion and acceptance is a major step towards the assembly of the complete cryomodule. However, it is just the start of a long journey from CERN to the assembly of the subcomponents in the UK.

By Thomas Demaziere and Alejandro Castilla, on behalf of WP4.

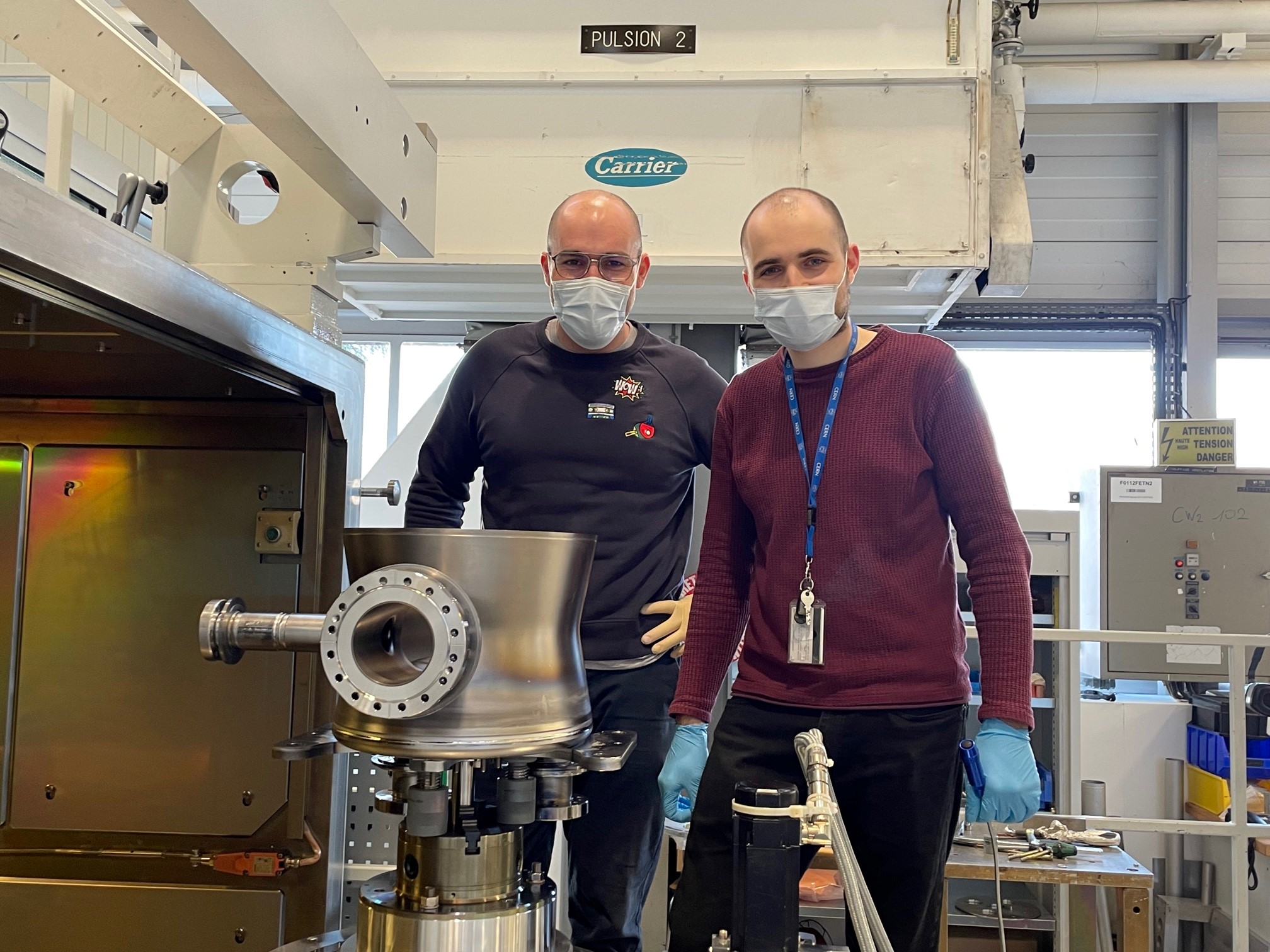

Thomas Demaziere and Manuel Redondas on the day of the subcomponents welding (Image: Simon Barriere)