By Thomas Bauler and Paolo Fessia (CERN)

2024 was a challenging yet fruitful year for logistics and installation of the general services of the new HL-LHC galleries at CERN Points 1 and 5. 2025 will be a key year for the HL-LHC project with the phase of installation of large machine technical equipment kicking off in the HL-LHC surface buildings and underground galleries.

At the end of 2023, the work site was left with its two shafts, PM17 and PM57, blocked by scaffolding. This created a very complex logistical situation. To not to hamper the advancement in the underground, the coordination team had to plan and stock enough components in order to work whilst the deliveries to the underground via the shafts were not possible.

Figure 2. Scaffolding at HL-LHC Point 1 (left) and Point 5 (right) galleries in 2023. Thomas Bauler / CERN.

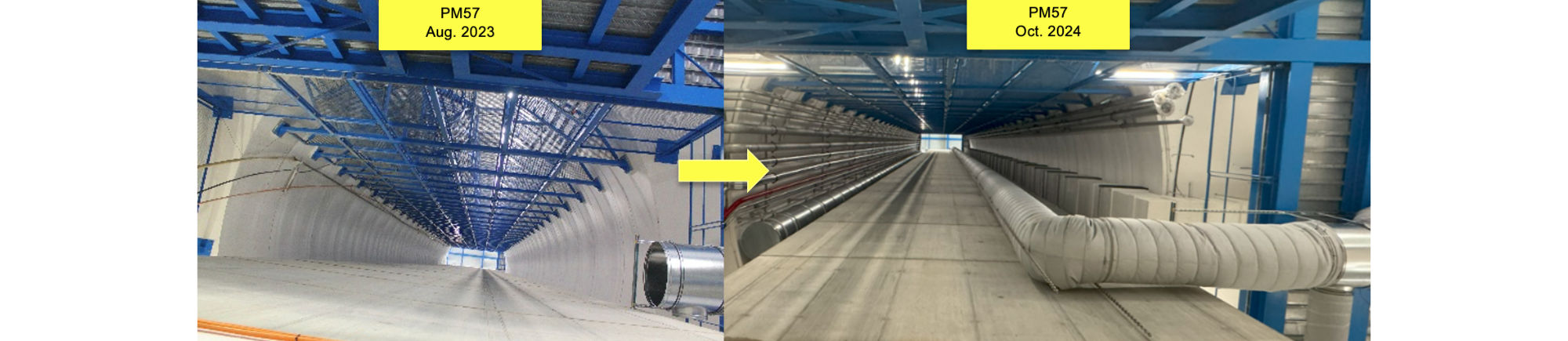

In early 2024, the project succeeded in finishing the installation of all pipes, ducts and high-power cable pulling in the shafts connecting the surface to the underground. This phase done, the 80-metre-long scaffolding could be removed and the worksites were able to install new deliveries.

For the first time at CERN, an underground installation was equipped with a smoke extraction system. This is one of the key ingredients that will guarantee safe working conditions in the HL galleries allowing access to the HL underground infrastructure even during machine operation. The final aim: to provide solid and reliable equipment exploitation to guarantee a very high machine availability for physics exploitation.

Figure 3. HL-LHC underground galleries at Point 1 in December 2024 (left) and January 2025 (right). Florence Thompson / CERN.

This 400-metre smoke duct extraction, allowing extraction of fumes to the surface in the case of incidents, has been built from calcium silicate plates capable of withstanding exposure to very high temperatures. The onsite construction of such a long conduit, making use of mineral based plates, has required careful logistical organisation, to avoid having to stop other activities, and attentive execution, to reach the leak tightness requirements. In parallel, the ventilation duct has been mounted and is expected to be commissioned in 2025.

The first challenge of 2025 will be the installation of the cryogenic distribution line (QXL). The QXL will be installed in two main phases, the first targeting the part of the line to be hosted in the new underground (2025), and the second completing the distribution to the equipment on the beam line (2027).

A second major cryogenic worksite will also start in 2025: the refrigeration part. This multistage system will require the installation of the warm compressors station in the SHM building on the surface, the 4.5 K refrigerator in the SD building, and the 1.9 K refrigerator and valve box in the underground galleries. The latter will be connected to the QXL, while surface and underground units will be linked via vertical 80-metre transfer lines. The SD building and SHM building equipment is connected by the hundreds of metres of pipes running in the surface technical galleries. These pipes were installed in 2024 at Point 1 and installation in Point 5 is expected to be completed in the first quarter of 2025.

The water-cooled cables, the first elements of the powering distribution for the HL-LHC superconducting magnets will also be installed this year.

In order to cope with the increased complexity of the installation, since the start of 2025, the HL-LHC project has had a de-installation and installation technical coordinator in place to oversee the activities of the various work packages and actors, ensuring at the same time the application of the relevant safety requirements.

Figure 4. Shaft at Point 5 before and after removal of scaffolding and installation of the smoke extraction duct, temporary ventilation duct and cooling pipes. Henry de Maynard / CERN.