By Tomas Pereira Nave Henriques Da Silva (CERN)

All 83 of the new deformable RF modules, key components to link adjacent vacuum chambers in the LHC, have been produced at CERN, marking a significant milestone for the HL-LHC project.

Production involved multiple complex fabrication and coordination stages, with all parts (apart from the bellows) manufactured at CERN’s Main Workshop using advanced machining and surface treatments.

What are warm vacuum interconnections?

Warm vacuum interconnections are key components that link adjacent vacuum chambers in the LHC’s warm sectors (the sectors not under cryogenic temperatures). They ensure vacuum tightness, accommodate chamber misalignments, compensate for thermal expansion/contraction, and reliable electrical continuity with low beam impedance (interaction of charged particles in the beam with the surrounding environment).

New generation of interconnections for the HL-LHC

For the HL-LHC, a new generation of warm vacuum interconnections has been developed, introducing a deformable RF (DRF) contact bridge instead of a conventional RF finger design, increasing tolerances for misalignments to up to 5 mm (versus up to 2 mm today). This substantially improves the reliability of the contact between the DRF insert and the transition tube, as well as mechanical robustness by avoiding potential loss of beam aperture due to RF finger buckling or beam induced pressure spikes following RF contact loss.

These vacuum interconnections differ in aperture size according to their functional position within the LHC, while maintaining a common design philosophy.

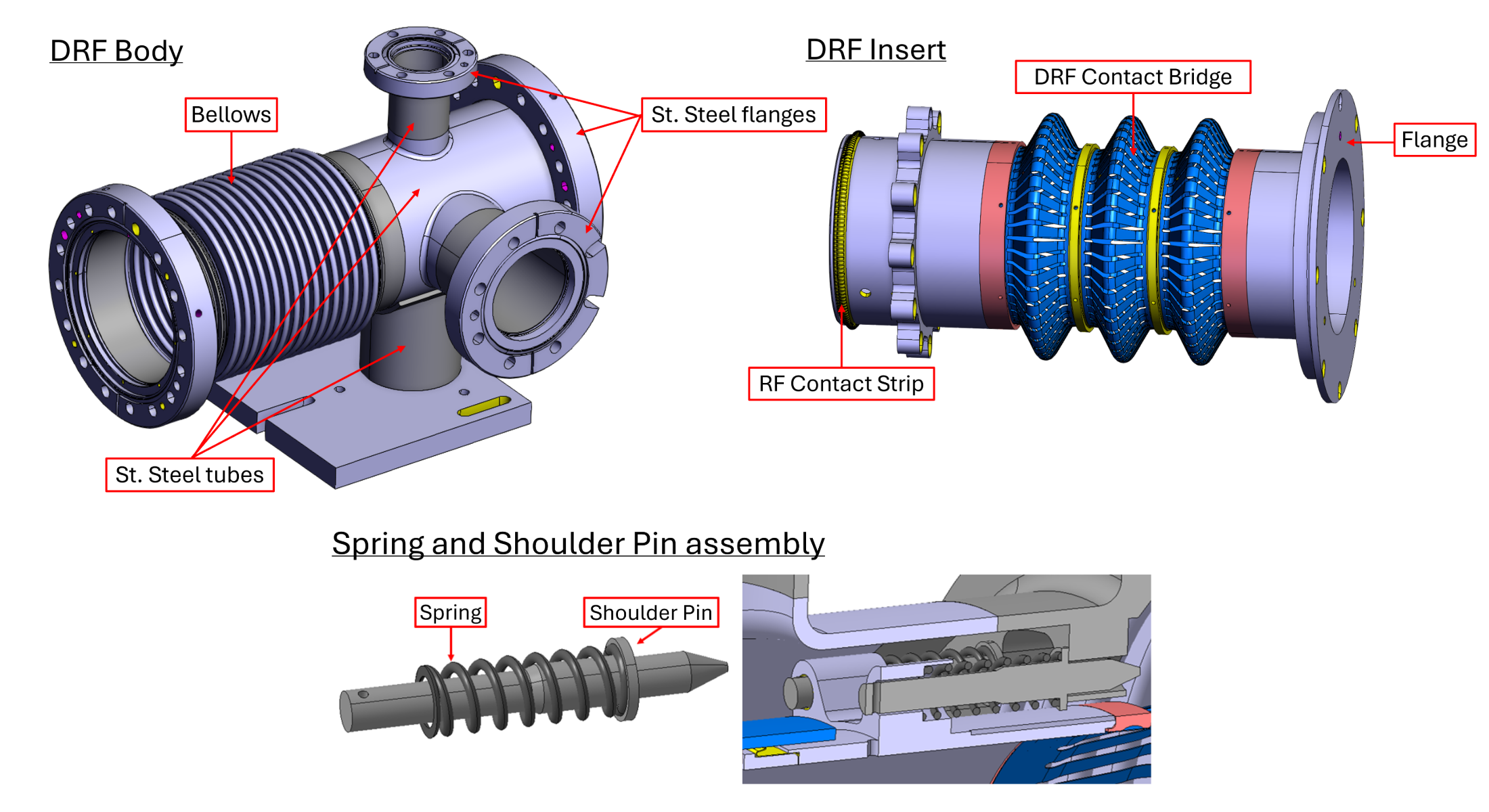

Figure 2. DRF body, DRF insert and spring and shoulder assembly. Tomas Pereira Nave Henriques Da Silva (CERN)

What does each part of a DRF module do?

The module body of each DRF module is made from stainless steel flanges, bellows, and tubes, welded together. It allows flexibility for installation and thermal cycles. The DRF insert consists of the new flexible contact bridge, flange, and contact strips to maintain a good electrical contact even in the case of mechanical shifts and temperature changes during operation and at the same time lowering resistance for the particle beam.

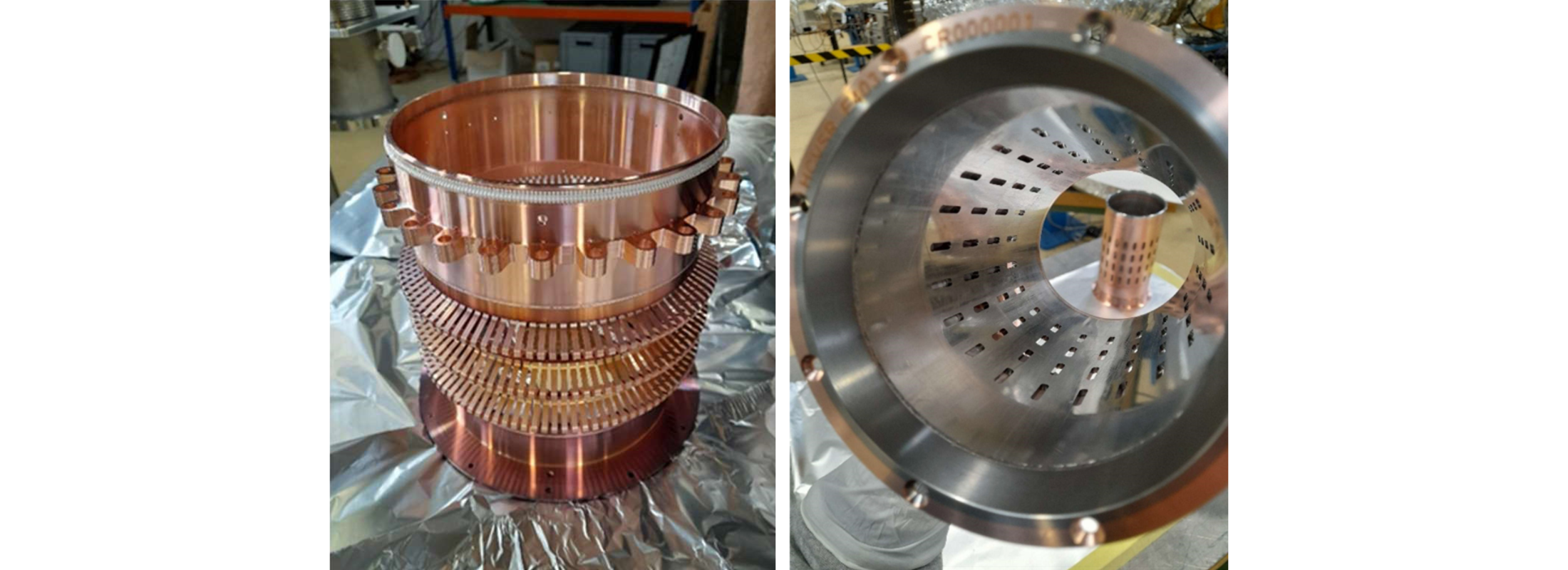

The transition tube is a copper tube which is rhodium-coated to ensure low-resistance current transfer and long-term stability. Depending on the installation location, the inner surface may be treated with a non-evaporable getter (NEG) coating, an amorphous carbon (aC) coating, or left uncoated. These coatings improve vacuum performance and lower the secondary electron yield (SEY). It may include pumping slots depending on requirements.

The spring & shoulder pin assembly are inconel springs with shoulder pins, to link the insert to the body. The spring count increases with aperture size, ensuring sufficient restoring force to keep the module in position.

What's next?

A total of 83 DRF modules (diameters DN63, DN150, DN212, DN250) are destined for installation in the LSS1 and LSS5 regions (the long-straight sections 1 and 5 of the LHC). To date, all components have been produced, leak-tested, cleaned for ultra-high vacuum (UHV) applications, and are undergoing final acceptance testing before installation.

Figure 3. DRF insert DN250 (left), and transition tube DN63 with NEG coating (right).