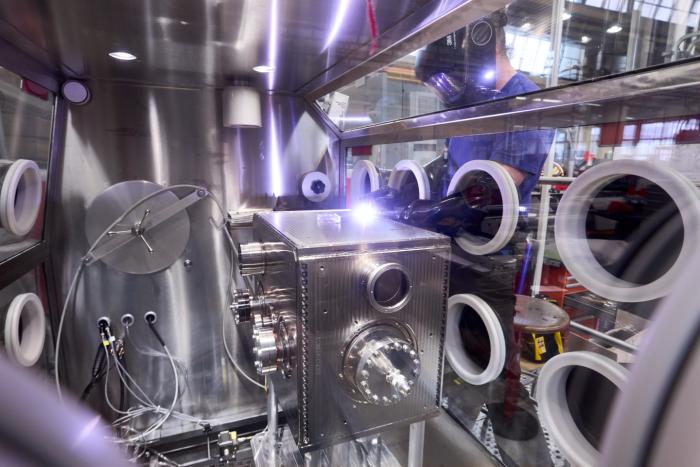

A titanium grade 2 helium vessel was TIG welded around a superconducting Double-Quarter Wave LHC Crab Cavity. The welding was performed inside a special glovebox under a controlled atmosphere at CERN EN-MME Main Workshop. The titanium tank will be filled with 2K superfluid helium to reach the superconducting properties of the bulk niobium cavity and maintain the structural properties during the operational cycle and corresponding pressure transients.

This cavity, fully manufactured at CERN, will then be tested at the SM18 SRF facility and string assembled in a ISO4 clean room with its twin, manufactured in 2022, before their installation in the first series LHC DQW cryomodule.

The superconducting radio frequency crab cavities are essential components for the High-Luminosity LHC project, as they will help increase the luminosity reach by restoring head-collisions at the interaction points.

By Simon Barrière and Rama Calaga.

Related photo collection: link.