By Nicolas Heredia Garcia (CERN)

Following the installation of the superconducting link, significant progress has been made on the IT String test facility, part of the High Luminosity Large Hadron Collider (HL-LHC) upgrade project. Among the components installed, the Q2a and D1 cryoassemblies stand out. These items, containing state-of-the-art superconducting magnets, are now positioned in their final locations in the IT String magnet line inside the SM18 building, marking a steady advancement towards the commissioning and operation of this unique test stand.

The installed Q2a cryoassembly contains an MQXFB quadrupole magnet developed and produced at CERN, as well as a dipole corrector magnet. The new quadrupole magnets for the HL-LHC feature a larger aperture (increasing from 70 mm to 150 mm), a higher peak magnetic field (increasing from 8.6 T to 11.3 T), and they use Nb3Sn superconducting material, instead of the more traditional NbTi which is employed for all LHC magnets presently installed. These magnets can achieve a much increased focusing of the proton beams to obtain the desired collision rates at the CMS and ATLAS experiments.

Susana Izquierdo Bermudez, CERN Work Package 3 (WP) MQXFB engineer, noted, “Today, Nb3Sn is the superconductor that reached the required level of maturity to be considered as a candidate material to reliably reach magnetic field levels above 10 T. This pursuit of higher magnetic fields translates into challenges for the magnet design and construction. A major milestone for the technology will be the first-time implementation of Nb3Sn quadrupole accelerator magnets in the HL-LHC. After more than 20 years of development, the production of 36 Nb3Sn accelerator-quality magnets—12 by CERN and 24 by U.S. laboratories BNL, LBNL, and Fermilab—is currently underway, paving the way for the next generation of magnets.”

The Q2a also houses the nested dipole corrector magnet MCBXFB, fabricated by the Spanish institute CIEMAT and CERN. This magnet allows correction of the particle beam trajectory by generating a magnetic field of up to 4.1 T. Juan Carlos Perez, CERN WP3 MCBXFB engineer, highlighted its complex mechanics: “The novel mechanical structure is designed to withstand the large electromagnetic forces generated by two dipoles oriented at 90 degrees and capable of producing a magnetic corrector field covering 360 degrees. The torque induced during operation can be up to 100 times greater than that generated by the most powerful electric car engines currently available.” He also recalled that, “the MCBXFB is part of the PRISMAC project, a partnership between CIEMAT, CDTI, and CERN”.

The second cryoassembly installed in the IT String, known as the D1 Separation and Recombination Dipole, contains an MBXF magnet. Its role in the HL-LHC is to separate and re-combine the two proton beams traveling together in a single 150 mm-aperture beam pipe near the detectors, guiding them into two distinct beam pipes and vice versa. The magnet’s NbTi strand coils enable it to generate a magnetic field of 5.6 T when powered at 12.1 kA and operated at 1.9 K. This magnet was manufactured and tested at the KEK institute in Japan together with its industrial partner as part of an international collaboration with CERN. Tatsushi Nakamoto, the project engineer in charge of this in-kind contribution from KEK, recently visited the IT String facility and commented, "This achievement marks a significant milestone in our partnership with CERN and in particular for the HL-LHC project.”

Regarding the installation sequence of Q2a and D1 in the IT String, the process began with the integration and pre-alignment of the support posts for the cryoassemblies, commonly known as jacks. These jacks are part of the cash contribution from the Serbian Ministry of Education, Science, and Technological Development to the HL-LHC Project. The jacks for the HL-LHC IT String were fabricated by the company UNIOR components d.o.o. Preparatory works were also carried out on the jumpers connections towards the cryogenic distribution line (SQXL) to make them ready for connection to the magnets.

Once all was set up in the IT String, the installation was executed on the 25th of September for the Q2a and on the 4th of November for the D1. The manoeuvres took less than a day for each cryoassembly. They consisted firstly of transporting the cryoassemblies by truck to Point 1.8 and unloading them at the SMS18 building. Then, the cryoassemblies were moved to the SM18 facility using a ROCLA vehicle. To move the magnets closer to their final installation spots, an overhead crane was used. For Q2a, located beneath the platform, an additional step consisting of transporting the magnet by ground using an electric tow tractor was required. The final positioning onto the jacks was accomplished with a transfer table, following a similar procedure to the one used in the LHC machine.

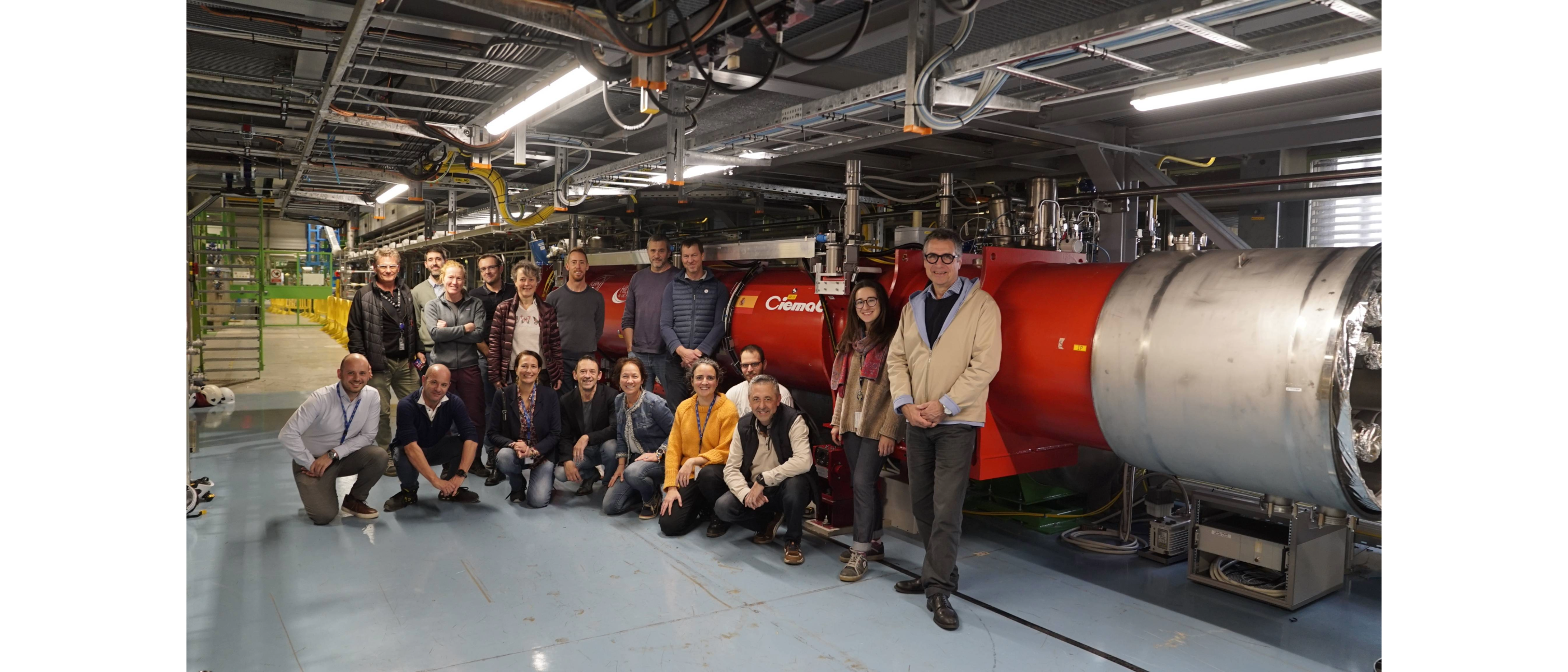

The complexity and precision required for these manoeuvres are evident, given the size and weight of the magnets; Q2a is 11 metres long and weighs approximately 19 tons, while D1 measures 9.8 metres in length and weighs 16 tons. Videos of the installation are available for both Q2a and D1 cryoassemblies. Davide Bozzini, technical coordinator of the IT String commented that the installation was carried out professionally and safely by the colleagues of the handling and transport group EN-HE, supported by the significant preparatory works made in joint collaboration by WP3 and WP16.

The next activities in the IT String will include receiving the remaining magnets, installing FRAS instrumentation and sensors on the arriving cryoassemblies, connecting the SQXL cryogenic distribution line to the magnets via jumper connections, and also executing quality control tests on various systems. Interconnection between magnets are scheduled for the first half of the next year. Following this, the focus will shift to commissioning and operating the test stand at nominal cryogenic temperatures.

Related videos

Cold Powering System installation

Related photo collections