By Juan Carlos Perez

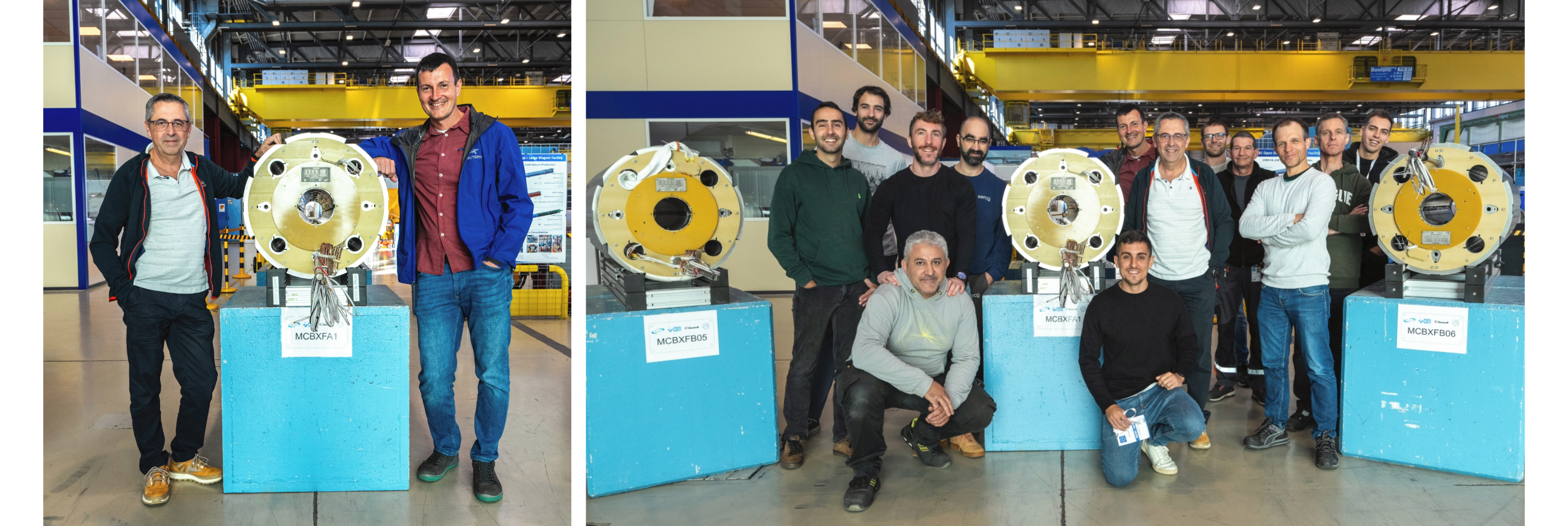

We have just celebrated the completion of the assembly of the third magnet at CERN facilities. Two have already been successfully tested, confirming their perfect operation within the required parameter window for installation in the HL-LHC cold masses. This follows years of dedication, and overcoming challenges in the production timeline in recent years. Juan Carlos Perez (CERN), explains.

The MCBXF corrector magnets will be installed in the LHC's insertion zones during the next technical stop (LS3), scheduled to begin in 2026 as part of the accelerator's luminosity upgrade project (HL-LHC).

Two types of magnets are currently being manufactured: the short 1.5-meter version, which will equip the cold masses containing the low-beta insertion quadrupoles (Q2a & Q2b), and the long 2-metre version, which will be used in the cold masses containing the higher-order correctors (Corrector Package).

The MCBXF magnets are orbit-correcting dipoles designed to compensate for particle beam trajectory deviations caused by alignment anomalies in nearby magnets. Within a collaboration agreement signed by the HL-LHC Project and CIEMAT (Madrid)in 2014 to provide these magnets as part of Spain’s in-kind contribution. Their 2-in-1 design, integrating two dipoles combined at a 90-degree angle to reduce the footprint within their respective cold masses, presents significant technical challenges in both design and production. The unique feature of these correctors is their ability to generate magnetic fields that can be oriented in any direction within 360 degrees, thanks to multiple power supply combinations for the two dipoles.

The trade-off for this flexibility is the management of very large electromagnetic forces generated during the powering of the magnets (the torque produced by the two dipoles can be up to 100 times that of the most powerful electric car engines currently on the market), making the mechanical structure's design and development highly complex.

The design and development process, carried out in close collaboration between CIEMAT and CERN teams, required several iterations during the prototyping phase, which continued until 2020, to achieve a reliable and robust configuration that ensures the required operational conditions for the machine's optics before validating their installation in the accelerator.

In 2021 a contract was awarded to industry for the production of 12 short MCBXFB magnets and 6 long MCBXFA magnets. After two years of production, and with only three magnets having been produced, the contract with the industry had to be terminated due to accumulated delays and the difficulty of producing magnets that met the required quality standards for the project.

Consequently, in October 2023, the decision was made to establish a production line replicating the setup that had proven successful during the prototype construction phase. CIEMAT became responsible for coil manufacturing and supplying the various components, while CERN became responsible for magnet assembly and testing.

The necessary infrastructure for these activities was set up in record time, both at CIEMAT’s new laboratory in Madrid and at CERN's Meyrin and Prevessin sites.

The third magnet at CERN facilities (Buildings 180 and 927) has now been completed, and two have already been successfully tested on the SM18 test bench, confirming their perfect operation within the required parameter window for installation in the HL-LHC cold masses.